Russian Automotive Market Research

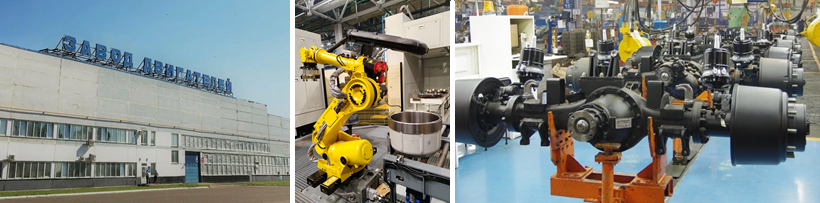

PJSC Tutaevsky Motor Plant, KAMAZ subsidiary in the Yaroslavl region, is completing the process preparation for the production of an upgraded tractor engine. Serial deliveries of this product to the customer will begin in July.

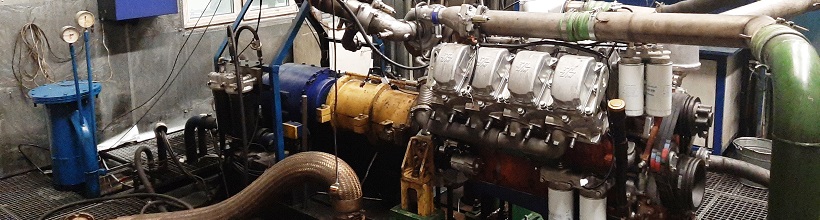

The upgraded engine will replace serial motors and will become the main one in deliveries to the assembly line of the St. Petersburg Tractor Plant (PTZ). Its main difference from its predecessors is the charge air cooling system with air–to-air charge air coolers and an 813 mm fan with an electrically controlled viscous coupling. The Kirovets K-7M tractor, for which the engine is designed, has also been upgraded. Innovations concern important tractor systems: hydraulics, control systems, and telemetry. It will also use a new radiator unit, including an air-to-air charge air cooler.