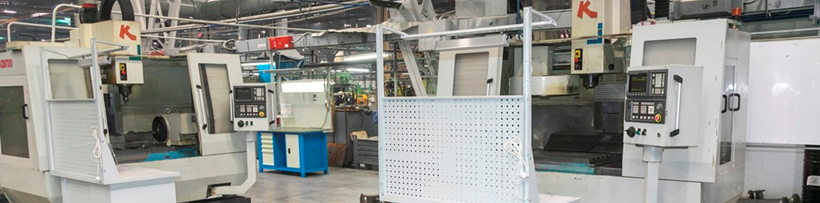

Six vertical milling machining centers with software control were delivered to the workshop of small steel parts of the KAMAZ Engine Plant.

The new equipment will be used in processing of parts for the V8 and P6 engines. According to Olga Brelyakova, Deputy Chief Engineer of the plant, the machines will ensure the smooth operation of the conveyor and close the need for the most in-demand parts - for example, nozzles, flanges, plugs, as well as transfer case parts. When designing the site, it was decided to arrange the processing centers in the form of a U-shaped cell – this will increase the efficiency of the production process.

Installation and commissioning works were carried out by specialists of the plant. Now they have been completed on two pieces of equipment, and the launch of the remaining machines is scheduled to be completed by May 1 of the current year.

NAPI (National Industrial Information Agency)