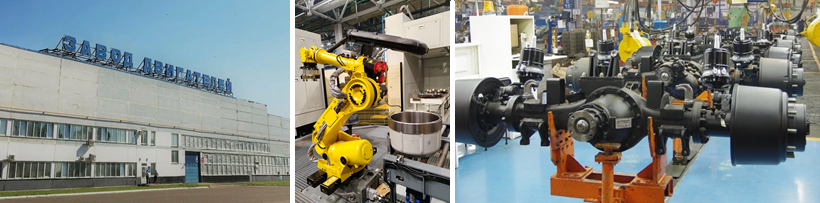

Commissioning of two robotic complexes is nearing completion within the Axles project at the KAMAZ Engine Plant, in the new product manufacturing shop.

Each complex consists of three vertical turning centers, which will be able to perform complete mechanical processing of two types of critical parts: rear wheel hubs and brake drums for hypoid axles of increased load capacity for K5 generation vehicles.

Robotic complexes are not the only acquisition at the production site. To complete the site, production furniture and cantilever cranes were also purchased, a tunnel-type washing machine for washing parts after mechanical processing and an ultrasonic bath for washing tools from metal-cutting machines were installed and put into operation.

NAPI (National Industrial Information Agency)