News

10/08/2022

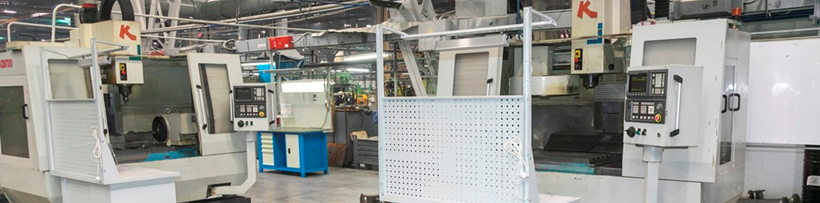

KAMAZ has optimized the tooling manufacturing technology

The KAMAZ forging plant improved the technology of manufacturing large-sized die tooling on CNC machines, which resulted in the reduction of the process complexity.

A specially created control program and the use of a new cutting tool made it possible to reduce the labor intensity of the process by up to 60% and provide the forging and pressing building No. 3 with uninterrupted and high-quality tooling manufactured on CNC machines for subsequent stamping of crankshafts and beams of the front axles.

NAPI (National Industrial Information Agency)

Other news from section:

23.04.2024

The Tutaev Motor Plant, KAMAZ subsidiary the Yaroslavl region, received six software-controlled machining centers.

According to Vladimir Shchanikov, Chief Engineer of TMP PTC, the machines are designed for machining cast iron cylinder heads. In the second half of March, the machines arrived at the plant and took their place. New equipment has been added to the machine park of the mechanical assembly shop. It is installed at a new production...

22.04.2024

Six vertical milling machining centers with software control were delivered to the workshop of small steel parts of the KAMAZ Engine Plant.

The new equipment will be used in processing of parts for the V8 and P6 engines. According to Olga Brelyakova, Deputy Chief Engineer of the plant, the machines will ensure the smooth operation of the conveyor and close the need for the most in-demand parts - for example, nozzles, flanges, plugs, as well...

Other research

Information

Market analysis